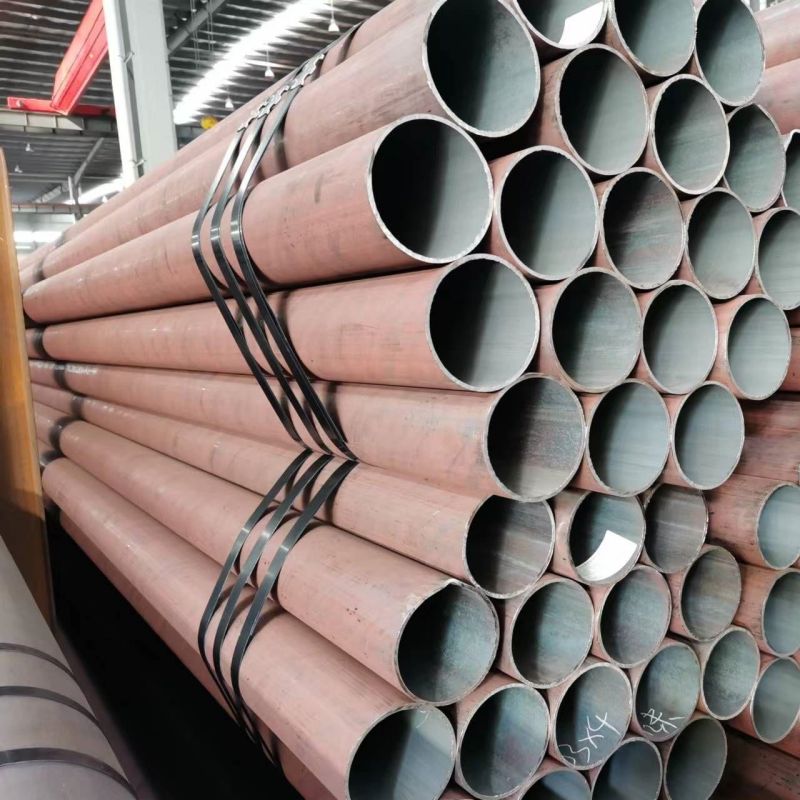

I-DIN 17175 yakhelwe izinjongo zokushisa eziphakeme, i-ANSON ihlinzeka ngokulandela amabanga ensimbi: St35.8, St45.8, 15Mo3, 13CrMo44, 10CrMo910.I-DIN 17175 amapayipi ensimbi angenamthungo asetshenziswa kakhulu ezintweni zokushintshanisa ukushisa.Leli banga eliphansi le-alloy linezengezo ezibalulekile ze-molybdenum ne-manganese kulo.Ngaphandle kokusetshenziswa kwayo ezinhlelweni zokubhayela, kuyasiza ekusetshenzisweni embonini kawoyela, igesi namakhemikhali.Ngokuvamile, lezi zimboni zisebenzisa izishintshisi zokushisa, njengendlela yokudlulisa ukushisa phakathi kwezixazululo ezimbili noma ngaphezulu.Amapayipi ngaphansi kwe-DIN 17175 akhiqizwa kusukela ku-carbon kanye ne-low-alloy steel amamaki aphikisana nemithwalo ngaphansi kwengcindezi ephezulu kanye namazinga okushisa.Zisetshenziselwa ukwakhiwa kwemishini yobunjiniyela bamandla njenge: ama-boilers, amakhoyili okushisa, izitofu, izifudumezi, amashubhu okushintsha ukushisa.

I-DIN 17175 amapayipi ensimbi angenamthungo asetshenziselwa ukufakwa kukabhoyela, amapayipi anengcindezi ephezulu kanye nokwakhiwa kwethangi kanye nemishini ekhethekile kokubili izinga lokushisa eliphezulu nemishini yokucindezela okuphezulu (Ngaphezu kwama-450 ° izinga lokushisa eliphezulu).I-ANSON ingumphakeli onolwazi lokubhayela kanye ne-pressure steel tube ongakunikeza ipayipi lensimbi elingu-DIN 17175 lalo lonke ibanga nobubanzi.