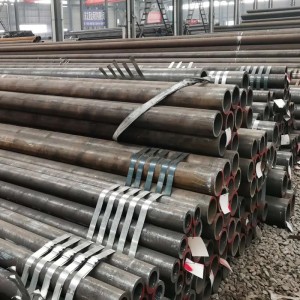

Njengamanje ipayipi elikhulu lensimbi elingenamthungo laseChina, inqubo yokukhiqiza eyinhloko igoqelwe ngokushisa futhi inweba ukushisa kwepayipi lensimbi elingenamthungo elinobubanzi obukhulu, ukucaciswa kwepayipi elishisayo elinwetshiwe elingenamthungo lika-325mm-1220mm ubukhulu obukhulu obungu-120mm, lingakhiqiza ukunwetshwa okushisayo kwepayipi lensimbi engenamthungo. Izilinganiso ezijwayelekile ezingezona ezezwe lonke, ukunwetshwa okushisayo okungenamthungo yilokho esivame ukukusho ukuthi ukunwetshwa okushisayo, ukuminyana kuncane kodwa ukufinyela okuqinile kwensimbi egoqelwe ngendlela etshekile noma indlela yokudweba ukuze kwandiswe ukushoda kwezinqubo zokuqeda ipayipi lobubanzi bepayipi.Esikhathini esifushane sokuqina kwensimbi ukukhiqiza izinhlobo ezingezona ezijwayelekile nezikhethekile zamapayipi angenamthungo, kanye nezindleko eziphansi, ukusebenza kahle kokukhiqiza okuphezulu, umkhuba wokuthuthukiswa kwamasimu okugingqika emhlabeni wonke namuhla.

Ipayipi elikhulu lensimbi elingenamthungo elikhulu ngomdwebo obandayo, imikhiqizo yensimbi egoqelwe ngokubanda, njengokwakheka okubandayo, ukwelashwa ngokushisa futhi ngaphandle kokulethwa okuqondile kwesimo okubizwa ngokuthi isimo esidonswa ngokubanda noma esigoqeka ngokubanda.Uma kuqhathaniswa nesimo esigoqekayo (sokubumba), isimo sensimbi (egoqiwe) enembayo enobukhulu obuphezulu, ikhwalithi enhle yendawo engaphezulu, ubuhwaqaqe obuphansi, kanye nezakhiwo eziphakeme zokusebenza, ngenxa yokudonswa kwensimbi edonswayo (egoqiwe) engaphezulu kwesimo se-oxide. ayimboziwe, futhi kunengcindezi enkulu, esengozini yokugqwala noma ukugqwala, futhi ngaleyo ndlela isimo sensimbi esidonswayo (esigingqiwe), ukupakishwa kwayo, izidingo zesitoreji ziqine kakhulu, ngokuvamile zidinga ukugcinwa endaweni yokugcina izinto, futhi kufanele sinake. isikhwama sokulawula izinga lokushisa nomswakama.